The new process of electric desalting wastewater treatment solves the problem of refining and chemical industry

1.electricity desalination wastewater generation and treatment difficulties

Crude oil often contains salt, water (dissolved in oil or in an emulsified state) and needs to be removed by an electrical desalting process before entering the distillation unit. The electrodesalination process produces about 3% of the refinery's total wastewater, known as electrodesalination wastewater.

The electrodesalination wastewater will have an impact on the downstream sewage treatment unit, and usually needs to be treated effectively before entering the integrated sewage treatment plant for treatment.

In recent years, the problem of heavy and inferior crude oil is becoming more and more serious. In order to improve the production and transport rate, the amount of water injection and injection agent is increasing constantly, which makes the water quality of electrodesalination wastewater more complicated. At the same time, in order to improve the utilization rate of crude oil, the recovered heavy waste oil is mixed back into crude oil after preliminary treatment, which further intensifies the emulsification of crude oil and deteriorates the water quality of the electric desalting wastewater.

2.SINOKLE electricity desalted sewage treatment solutions

In the impact condition, the crude oil process can no longer treat the electric desalting wastewater. The plant has tens of thousands of square storage tanks as buffers, which occupy a large area and due to the addition of chemical agents, the water content of the dirty oil is high, and the waste residue cannot be treated, and the dirty oil drying device is also needed, and the operation cost is high.

For the problem of electrodesalinized wastewater treatment, SINOKLE has combined our core technology product -- Cyclonic Dissolved gas Flotation Unit (CDFU). By combining centrifugal separation technology, dissolved air flotation separation technology and ultrafine bubble generation technology, the wastewater containing oil and suspended matter can be separated efficiently.

Site diagram of CDFU industrial plant of a petrochemical enterprise in Xinjiang

Due to the poor water quality in the impact condition of the plant (up to 40% slag content), the degreaser + two-stage CDFU swirling dissolved gas flotation process is adopted. The degreaser and primary CDFU swirling dissolved gas flotation are separated by physical demulsification technology to remove most of the dirty oil, and the dirty oil is collected and recycled.

Schematic diagram of electric desalting wastewater treatment process

Only a small amount of flocculant is added to the secondary CDFU cyclone air flotation, and the effluent is clear and clear, reaching the reception index of the sewage plant.

Site pilot equipment drawing

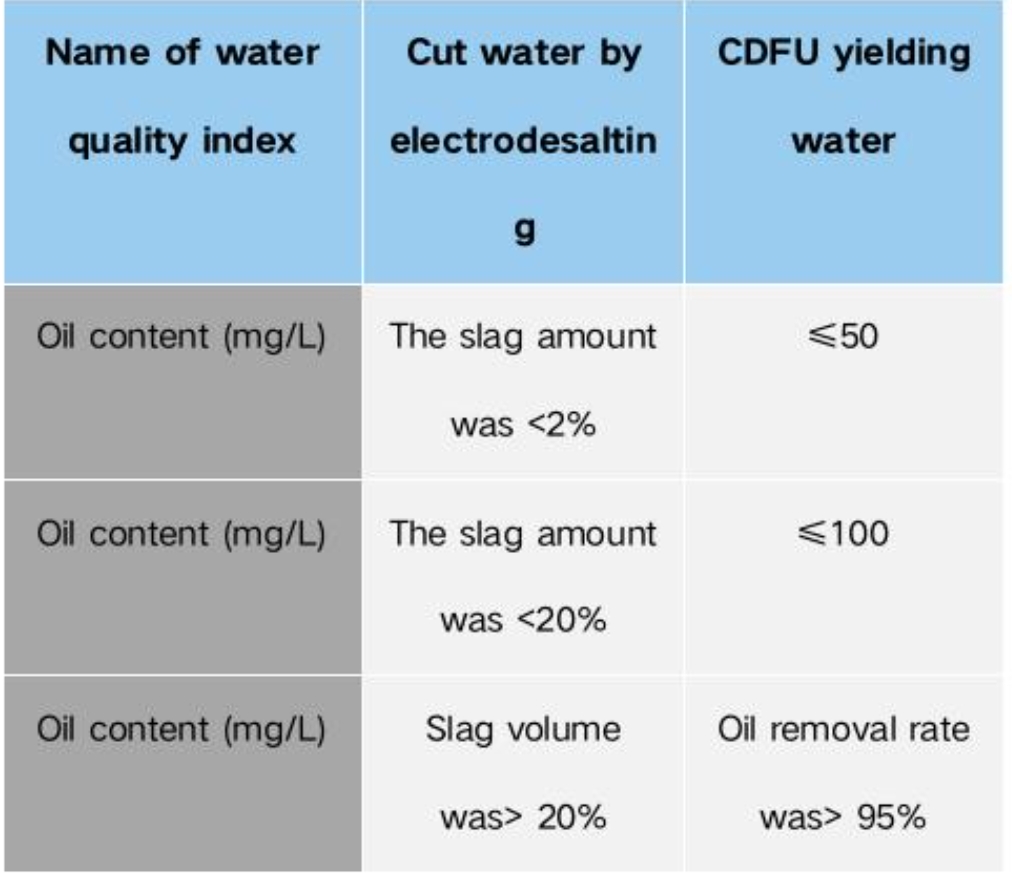

3. water inlet and outlet indicators

Project water inlet and outlet indicators

4. Treatment effect

From left to right: water inlet, oil remover outlet, primary CDFU outlet, secondary CDFU outlet