Oil field, offshore platform production water reinjection treatment technology

After the oilfield is put into development, with the growth of mining time, the energy of the oil reservoir itself will continue to be consumed, resulting in a continuous decline in the pressure of the oil reservoir, a large amount of underground crude oil degassing, increasing viscosity, greatly reducing the output of the oil well, and even stopping the injection and production, resulting in a large amount of dead oil remaining underground. In order to make up for the underground hole caused by crude oil production, maintain or increase the reservoir pressure, achieve high and stable production and obtain higher recovery rate, it is necessary to inject water into the oil field. According to the time of injection, oil field water injection can be divided into advance injection, early injection, middle injection and late injection.

The main sources of water injection are surface fresh water, shallow underground water and reservoir water produced at the same time as crude oil production. At present, most of the water injected into the reservoir comes from the extracted crude oil, which has accounted for about 80% of the total water injection. According to the different properties of the oil reservoir, different water quality standards are applied, but in general, the water quality of the injection should meet the following points:

1. The injected water should contain as little suspended impurities as possible, and its content and particle size should not block the penetration end face of the injection well and the oil reservoir.

2, the injected water quality does not cause scaling and precipitation due to changes in temperature, pressure, etc., nor can it cause scaling or precipitation when the formation water or surface water is mixed.

3. The injected water quality does not corrode the water injection equipment.

4, the reproduction of bacteria injected into the water can not produce new suspended impurities, and can not affect the normal work of the water injection system.

5. The injected water quality should prevent the expansion of oil layer clay.

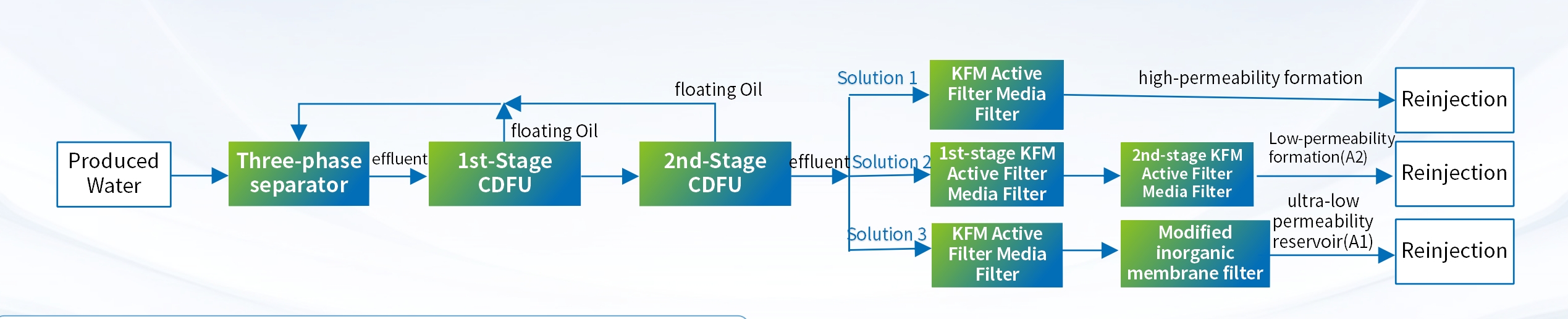

In response to the above requirements, Shenzhen Keli Technology Co., Ltd. independently developed the oil depot, oil field, offshore platform production water reinjection treatment process:

The process can be used for both conventional oily wastewater treatment and low poly oily wastewater treatment. In addition, the high efficiency dissolved air flotation is used to replace the gravity settlement of the large tank, and the physical demulsification of micro-bubbles is pure, which reduces the production of oily sludge. The process has the advantages of short process flow, compact equipment, short residence time, high processing efficiency and small footprint. Equipment skid, intelligent, can achieve unattended automatic operation; The process runs stably, the impact resistance is strong, and the water quality is stable and up to standard.

Practical engineering cases are applied as follows:

FIG. 1. Produced water treatment site of an oilfield

Figure 2. Comparison of water inlet and outlet of equipment