Treatment technology of acidic coking wastewater

Acidic coking wastewater is a kind of water which contains many pollutants such as sulfide, ammonia, phenol, cyanide and oil when processing sour crude oil in refinery. Because it contains a variety of harmful substances, acidic coking wastewater can not be directly discharged into the sewage treatment plant, and its treatment is very important for environmental protection and sustainable development. This paper will discuss the formation of acidic coking wastewater, treatment difficulties and existing treatment technology, and explore innovative treatment direction.

Acidic wastewater treatment faces some challenges. The use of steam stripping is the main treatment process, but it requires a lot of energy consumption, resulting in energy waste, and the steam generated during the treatment process needs to be further treated. In addition, the waste water contains toxic gases such as hydrogen sulfide, ammonia, etc., which need to be effectively controlled and treated to ensure the safety of workers.

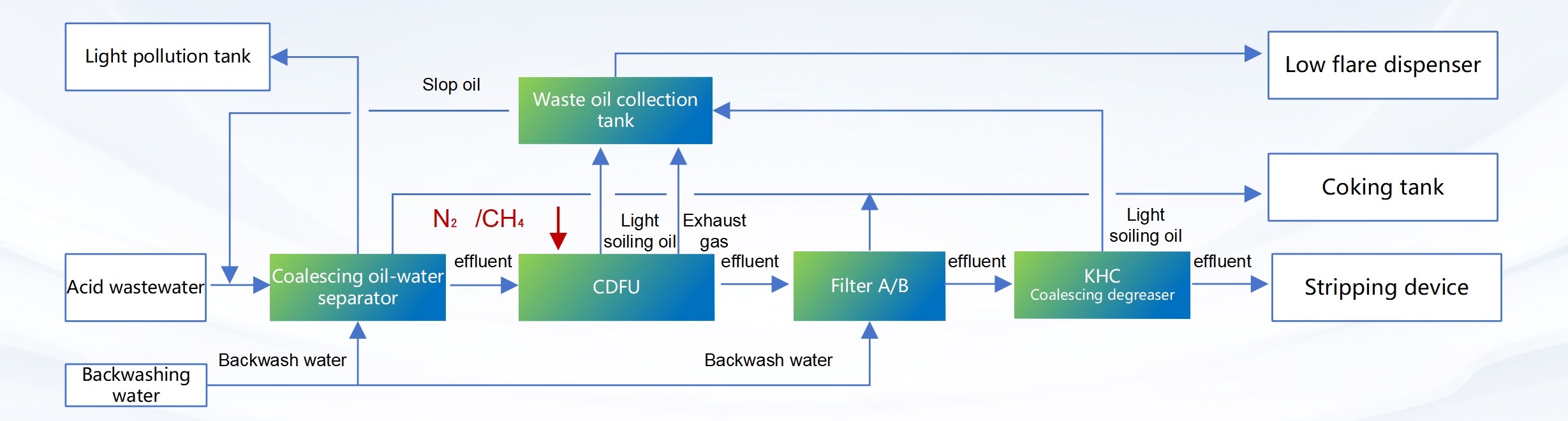

For the treatment of acidic coking wastewater, SINOKLE proposed a new process to treat acidic coking wastewater. The specific process flow chart is as follows:

Coking acid wastewater treatment process flow chart

Compared with the traditional process has the advantages of pure physical separation technology, stable and reliable and high oil removal efficiency;

No chemical pure physical emulsion and oil removal, recovery of high-quality light pollution oil direct reuse, no secondary pollution, no oily sludge (hazardous waste), solve environmental problems and create economic benefits; The process is reliable and stable, the equipment structure is compact, and the floor area is small; Skid installation, automation, simple operation and maintenance, short construction period, can be implemented online; Strong impact resistance, stable operation, can withstand large water quality fluctuations.

Among them, CDFU and KHC coalesce degreaser are self-developed products of Keli and have obvious advantages over the machinery used in the traditional process.

CDFU: Swirl dissolved air flotation is a new generation of green and efficient vertical tank air flotation equipment developed by us. The equipment integrates swirling centrifugal separation technology, ultrafine bubble generation technology and dissolved air flotation technology. Through the organic combination of multiple technologies, it can achieve efficient and rapid separation of dirty oil, emulsified oil and suspended matter in sewage.

KHC coalesce deoiler: Through the use of super lipophilic and hydrophobic coalesce fiber materials and intrinsic design, integrating a series of technologies such as swirling centrifugal separation, wet coalesce, collision coalesce, and interception filtration, to achieve efficient coalesce, separation and removal of emulsified oil in sewage.

A petrochemical company coking acid wastewater treatment plant site

Application case

Treatment effect of emulsified acidic wastewater

Project information:

Inlet sewage oil content: ≤ 150000ppm

Capacity: 15m3/h

Main equipment: CDFU+KHC efficient coalescent oil remover

Water oil content: ≤ 100ppm