Electricity Desalting Wastewater Treatment Process: Coalescing Oil Remover + CDFU Cyclonic Dissolved Gas Flotation

Electricity Desalting Wastewater Treatment Process: Coalescing Oil Remover + CDFU Cyclonic Dissolved Gas Flotation

- Overview of Electricity Desalting Wastewater Treatment Process

Electricity desalting wastewater treatment is a crucial link in refinery operations, primarily aimed at removing oils and other pollutants from wastewater to meet environmental discharge standards. With the deterioration and complexity of crude oil quality, traditional treatment technologies such as gravitational separation, hydrocyclones, and coalescing methods have become insufficient to meet the demands of modern refineries. Therefore, the development of new treatment processes and technologies has become an inevitable trend.

- Traditional Treatment Technologies and Their Limitations

Gravitational Separation

Gravitational separation leverages the density difference and immiscibility of the oil-water phases for separation. However, for electricity desalting wastewater containing a large amount of fine suspended particles and severely emulsified oil, this method yields poor results.

Hydrocyclones

Hydrocyclones utilize centrifugal separation technology through swirling flow. However, under conditions of drastic fluctuations in oil content, it is difficult to stabilize the effluent oil content to meet standards.

Coalescing Method

The coalescing method increases oil droplet size, enabling faster separation by floating. It has strong shock resistance. However, its effectiveness is limited when treating severely emulsified electricity desalting wastewater.

- Emerging Treatment Technologies

High-Efficiency Coalescing Pressure Oil Remover

The high-efficiency coalescing pressure oil remover developed by [Company Name] (placeholder for actual company name) achieves efficient oil-water separation through bidirectional flow design and CFD-optimized internal flow fields. The device is compact, easy to operate, safe, and reliable, making it suitable for treating electricity desalting wastewater.

Cyclonic Dissolved Gas Flotation Unit (CDFU)

The CDFU combines cyclonic centrifugal separation technology with dissolved gas flotation, offering high oil removal efficiency, small footprint, and strong stability. It is applicable to various types of difficult-to-treat oily wastewater.

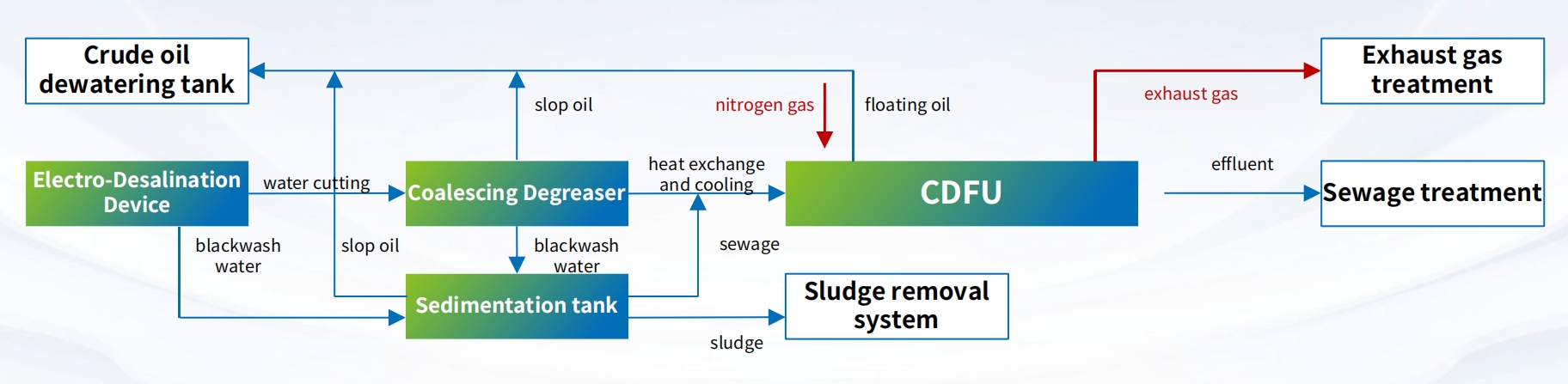

- Integrated Treatment Process

To enhance the treatment effectiveness of electricity desalting wastewater, an integrated treatment process such as the "High-Efficiency Coalescing Oil Remover + CDFU Cyclonic Dissolved Gas Flotation" combination can be adopted. This combined process achieves efficient oil-water separation through the organic integration of multiple technologies.

- Practical Application Cases

These emerging technologies have been successfully applied in large refineries such as Sinopec and CNPC, demonstrating remarkable treatment results. For instance, the application of [Company Name]'s (placeholder) high-efficiency coalescing pressure oil remover and cyclonic dissolved gas flotation technology in an electricity desalting wastewater treatment project at a petrochemical enterprise in Hebei resulted in influent wastewater with an oil content of ≤20,000 ppm being treated to achieve an effluent petroleum index of ≤50 ppm, showcasing strong shock resistance.

- Conclusion

In summary, electricity desalting wastewater treatment processes are evolving towards greater efficiency, stability, and environmental friendliness. Through continuous research and development, and the application of new technologies, we can effectively address the various challenges in electricity desalting wastewater treatment, ensuring the long-term, safe, and stable operation of refinery production.