Treatment of Highly Emulsified Acidic Water in Coking

Product Detail

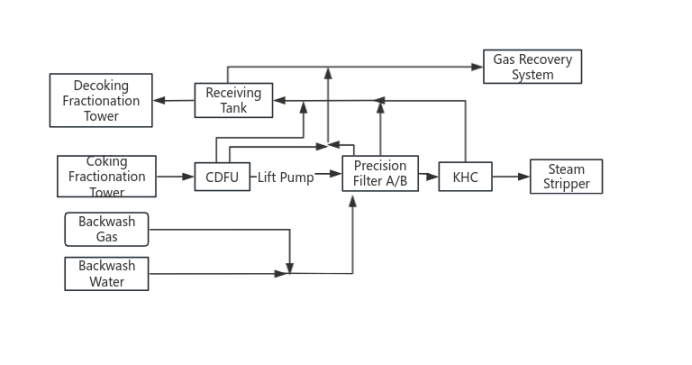

Process Flow

Technological Advantage

The overall process is advanced, with good reliability and stability.

Efficient separation is achieved using CDFU, relying on the density difference of oil-gas-water three phases to remove oil and suspended solids effectively.

A fully automatic fine filter is employed, providing high precision and deep filtration of suspended solids to enhance process reliability.

Patented coalescing packing and high-precision coalescing cores imported from the United States are used for rapid and thorough emulsion breaking.

The fully enclosed automatic control operation ensures no acidic gas leakage, ensuring safety, environmental friendliness, and reliability.

Designed for modularization, it occupies a small footprint, boasts high automation levels, and has low operational and maintenance costs.

Technical Comparison

| No | Traditional Technical | SINOKLE Solution |

| Separation Principle | Traditional air float + Membrane filter/filter + Coalescer | CDFU + Coalescence |

| Emulisified Oil Removal | Some emulsified oil can be removed | Most of emulsified oil can be removed |

| Stability | Unstable, poor reliability | The effluent is stable and up to standard, with good reliability |

| Secondary pollution | Adding chemicals or acid and alkali washing, resulting in secondary pollution | No chemical pure physical demulsification separation, no secondary pollution |

| Recovery of waste oil quality | Partially demulsification, high in suspended solids and water, poor quality | Pure physical demulsification, low suspended matter and water content, high quality |

| Comprehensive cost | High energy consumption, pharmaceutical addition, high cost | Low energy consumption, no pharmaceutical, low cost |

| Automate | Low degree of automation,high operation intensity | Automation, intelligent advanced control technology, simple and convenient |

| Safety and environmental protection | Short maintenance period, high risk of dangerous operations | Long maintenance period, safety and environmental protection |

Application Case